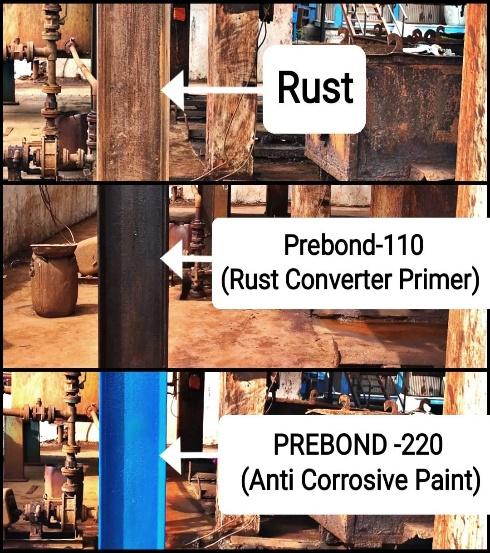

PREBOND-110 (Rust Converter Primer)

Rust Converter-cum Anti Corrosion Coating for Rusted Steel Structure Painting

DESCRIPTION: PREBOND-110 is a two-pack, water-based anti-corrosive rust converter-cum primer coating. It can be easily converting the rust and provide dark black anti-corrosive coating on the rusted metal surface, it reacts with rust (iron oxide) and chemically converts it to iron phosphate coating, which is very useful coating for long-term internal corrosion protection on old/heavy rusted metal. After application it protect the metal surface from further rusting for next 10*-12* months without paint and after painting 02*-03* years more in highly-corrosive and highly-acidic areas. After its application, no any types of primer coating required for painting.

PREBOND-110 is another unique solution to rust removing or sand-blasting for rusted steel structures for re-painting. It is an ideally suited to applications where rust removing, sand-blasting or surface preparation is a problem and is not practical or very expensive. For long-term anti-corrosive and acid, alkali resistant applications, apply PREBOND- 220 (Anti Corrosive PU Paint) 02 coats on rust converted surface for better results.